R-Cycle wins the German Sustainability Award 2021

19 Jul 2021

Digital plastic recycling

R-Cycle - the digital product passport for sustainable plastics - receives the German Sustainability Award 2021 in the "Packaging" category. The award is conferred by the German Institute for Service Quality (DISQ), the German news channel ntv, and DUP UNTERNEHMER (German Entrepreneurship Platform for Digitalization and Sustainability). The award is patroned by Brigitte Zypries, former Federal Minister (ret.).

Plastic packaging has become an indispensable part of our everyday lives and there is often no alternative - such as in medical technology or in the packaging of perishable foodstuffs. However, the problems associated with the growing global demand for plastic packaging cannot be overlooked and are becoming increasingly acute. For example, even in the "recycling land" of Germany, only about 6% of plastics from domestic waste are recycled to make equivalent new products. The largest percentage of over 65% is burned in waste incinerators*.

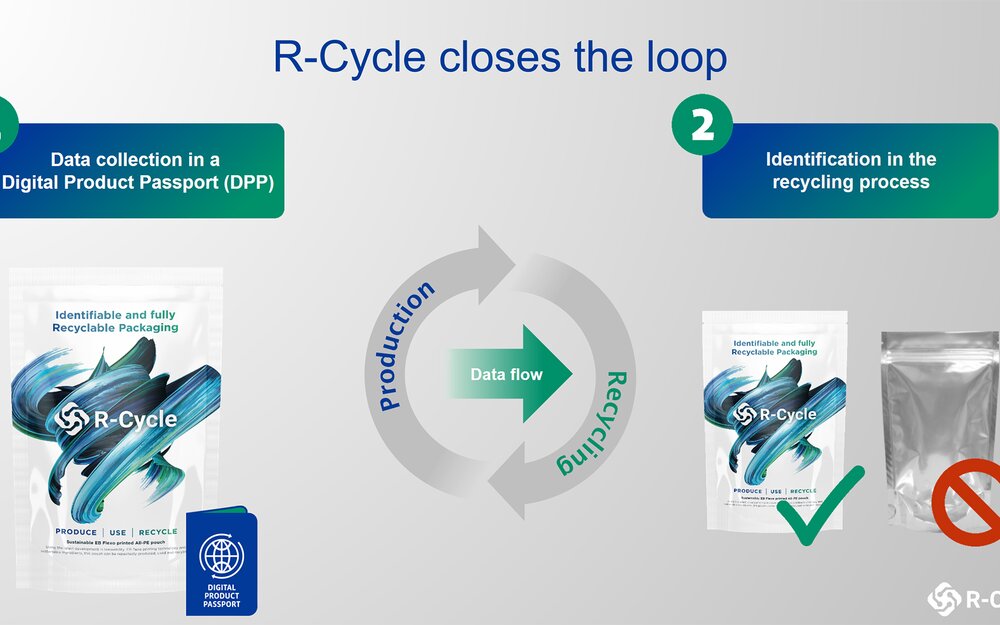

One reason for the low recycling rate is the present difficulty to identify the different compositions of plastic packaging in the recycling process. Sorting is considerably improved when a digital product passport is affixed to plastic packaging to display this information. R-Cycle is such a digital product passport. It is based on an open standard and is machine-readable via special markings. R-Cycle automatically registers all recycling-related properties during packaging production and passes this information along the value chain. Waste sorting plants can then identify recyclable packaging and form recyclable fractions. This is the basis for obtaining pure and therefore high-quality recyclates as part of efforts to set up a functioning circular economy.

"We are delighted to receive this award," says Dr. Benedikt Brenken, Director of the R-Cycle Initiative. "Digitalization and sustainability are two megatrends that we have integrated beneficially in R-Cycle. The use of a digital product passport, as also required by the European Union, offers enormous potential to increase the recycling rate of plastic packaging."

R-Cycle is under development to market maturity by leading companies and organizations along the entire plastic-packaging life cycle. Besides improving product sustainability, manufacturers can increase their process efficiency and product quality by using a digital product passport. Detailed information about the raw materials used speeds up production and registering the product properties adds value for customers in downstream processes.

*Conversio Study 2017 (Stoffstromdiagramm Kunststoffe in Deutschland) / Plastikatlas Heinrich Böll Stiftung

About R-Cycle

R-Cycle is a cross-company initiative to develop an open and globally applicable tracing standard for sustainable plastic packaging. The aim is to automatically record recycling-relevant packaging properties during production by providing a digital product passport and to pass them on through the value chain. Recyclable packaging can then be identified in the recycling process via special markings and fed into pure waste fractions. This is the key to obtaining high-quality recyclates to close the loop.

The R-Cycle consortium

ARBURG, Brückner Maschinenbau, COMEXI, EREMA GROUP, GS1 GERMANY, Institut für Kunststoffverarbeitung (IKV), KAMPF, KAUTEX MASCHINENBAU, MULTIVAC, PRODATA, REIFENHÄUSER GROUP, STEINERT

www.r-cycle.org

www.linkedin.com/company/r-cycle

www.twitter.com/RCycle5