Up to 6,000 infusion bags per hour at the best price-performance ratio

04 Aug 2023

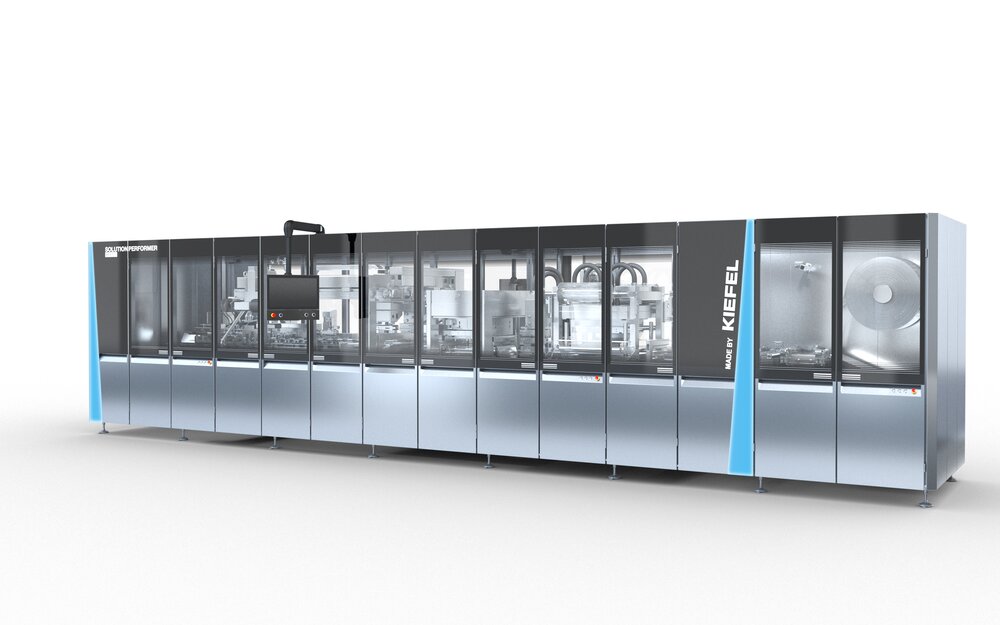

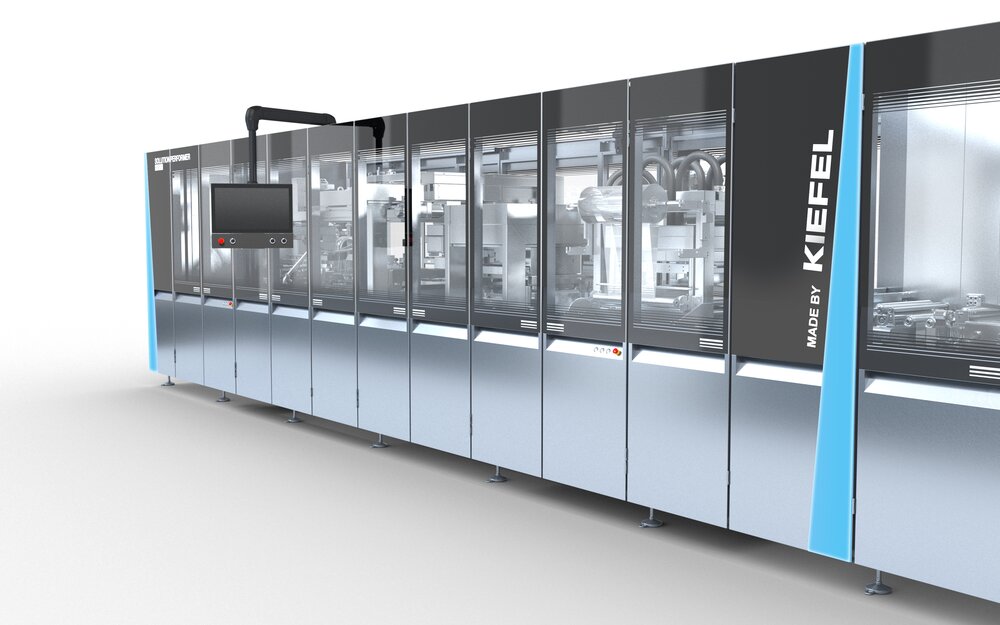

With the SOLUTIONPERFORMER, Kiefel is introducing a new generation of Form-Fill-Seal for medical and pharmaceutical polyolefin bags

As a leading company in thermoforming and joining technology, we are launching the new SOLUTIONPERFORMER KFS modular form-fill-seal machine for the medical and pharmaceutical market worldwide. Up to 6,000 infusion, parenteral nutrition or dialysis bags can be formed, filled and sealed fully automatically per hour on the system. The system is available in various formats, from the compact basic version for standard applications to individually configurable solutions.

Modular structure - to flexibly adapt to customer requirements

"With the SOLUTIONPERFOMER we have developed a new generation of a modular and optimally coordinated machine concept," states Thorsten Emge, Global Director Medical & Pharma at Kiefel. "With the best price-performance ratio, it meets the high requirements of our customers in terms of output, efficiency and bag quality."

The KFS line manufactures, fills and seals the bag on a single machine. Depending on the machine configuration and bag size, over 4,500 bags per hour can be equipped and filled fully automatically on the basic version, and even up to 6,000 bags per hour on the most powerful version.

Products are labeled and 100% traceable thanks to the option of printing and checking static and variable data.

High quality guaranteed

Whether tubes or injection-molded port connections, whether single-chamber or multi-chamber bags - there are almost no limits to the design of the bags, which can be customized from 50 to 6000 ml. "Due to its solid construction and process control, the SOLUTIONPERFORMER is designed for the highest possible product quality and product safety," states Thorsten Emge. The filling area of the system is prepared for Cleaning in Place (CIP) and Sterilization in Place (SIP).

The Kiefel system ensures maximum particle reduction, thanks to technologies such as film cleaning, a special tube cutting process and frictionless film guiding. Precision mass flow meters, optional residual oxygen content control and automatic sealing of the infusion, dialysis or nutrition bags ensure maximum output combined with constant quality monitoring.

Further advantages at a glance

The intuitive HMI simplifies machine operation and guides operators step by step through the tool change process in the event of product changes. Access rights for users are secured via user ID and password. Machine performance can be monitored at any time via the performance dashboard.

Equipment including track & trace, camera quality control and data transmission to mobile devices is optionally available. Servo motors are used instead of pneumatic drives in all relevant stations, to achieve both optimum process control and a reduction in compressed air consumption and therefore lower energy costs per article produced.

A fault diagnosis system and an integrated module for remote access in the event of a fault round off the equipment. Thorsten Emge adds: "In addition, our global service team is of course rapidly available to our customers worldwide as usual for all matters - either on site, by telephone or digitally".

Kiefel will also focus attention on the machine at this year's CPHI in Barcelona and at the Compamed in Düsseldorf.