Superb film properties with Brückner’s coating technology

21 Jan 2022

Turkish Polibak has extended their portfolio with high barrier inline coated films

Many properties of BO films are directly related to the surface characteristics of the skin layer. Especially for polyolefin-based materials, a further converting step is not beneficial without suitable surface treatment. To develop innovative treatment methods for BOPP, Brückner already started to invest in inline coating developments several years ago, to provide future-oriented solutions for film producers. Many resources and a lot of effort was invested to figure out new film types with improved properties.

The result: A complete knowledge package for the inline coating process of polypropylene films. It contains the required material recommendation, the necessary surface modification, and machine settings. Together with the advanced and field-tested coating equipment, Brückner delivers a reliable solution from one single source.

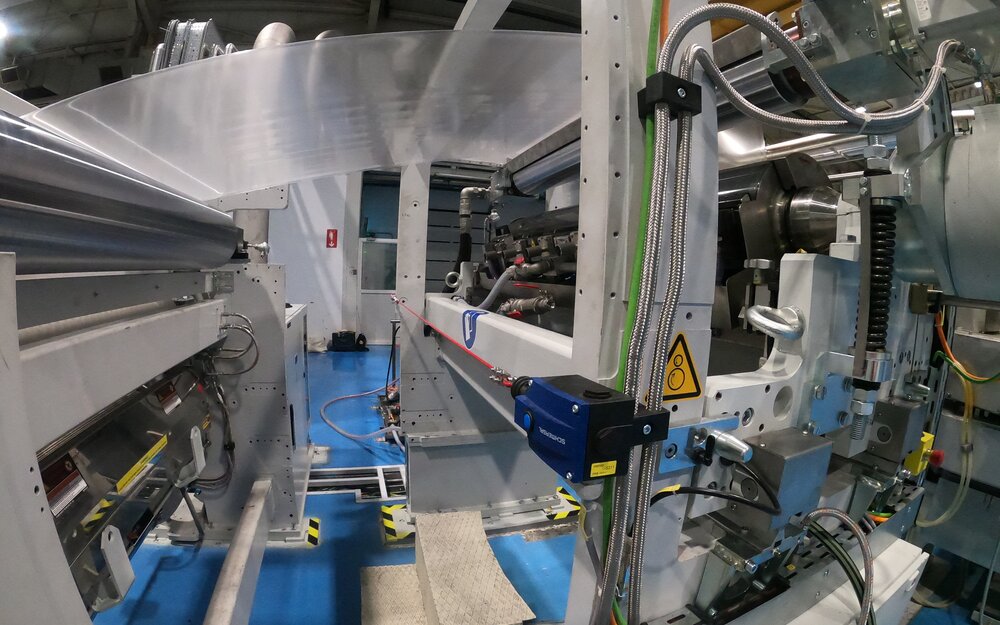

With this BOPP Inline Coating Technology, you can create for instance high-barrier films out of mono-material layers, which means they are fully recyclable. On top of that, you can give your packaging a transparent look with an AlOx coating. The coating equipment can also be integrated for upgrades in the existing production line to extend the product portfolio and make it more profitable.

And this is exactly what caught the attention of one of the leading Turkish plastic film producers, Polibak. The company planned to produce highly transparent, metalized barrier film, which is fully recyclable due to its mono-material structure, and with a minimal coating of aluminum oxide (AlOx). Therefore, an existing 10.4m 5-layer BOPP line had to be modified. Tamer Dalli, Polibak’s maintenance manager and head of the inline coater project explains their intentions behind the upgrade: “With the new film type we want to open up future markets. The first sample roles we produced shortly after upgrading our line have deeply impressed our customers. Especially Brückner’s recipes and material recommendations helped us to reach our goals quickly.”

Brückner Servtec’s project team wants to thank Polibak for the extremely smooth cooperation during all project phases. Although, the Covid crisis has caused continuous problems in the implementation process, the two companies worked hand-in-hand trustfully and the schedule was kept.