Kiefel – Higher quality and lower costs

21 Dec 2017

New FLF vacuum laminating process from Kiefel with the potential to save millions

What would the interior of a vehicle be without visually appealing surfaces on the doors, center console and dashboard? The higher the vehicle class, the higher the quality of the interior trim. Structured surfaces, a pleasant feel and everything manufactured at a high production quality are demands that the industry takes for granted. At the same time, the cost pressure for interiors continues to increase. A redesigned Kiefel vacuum-lamination process is the answer to these challenges.

Vacuum lamination applies the films to the interior linings. In order to significantly reduce component costs, KIEEFL GmbH, Freilassing, has developed a holistically innovative technology, taking a close look at and optimizing all process steps. The result is a unique vacuum lamination process - Flexible Lamination Frame (FLF) technology. With the help of FLF technology, the Freilassing specialists have managed to reduce material consumption and thus film costs by around 40 percent compared to conventional vacuum lamination processes. Also, the degree of film separation is significantly reduced and film stretching rates of only 10 to 15 percent are reached. Thus, the FLF vacuum lamination process comes close to the surface quality achieved with InMold-Graining laminating technology and is obviously a more cost effective alternative.

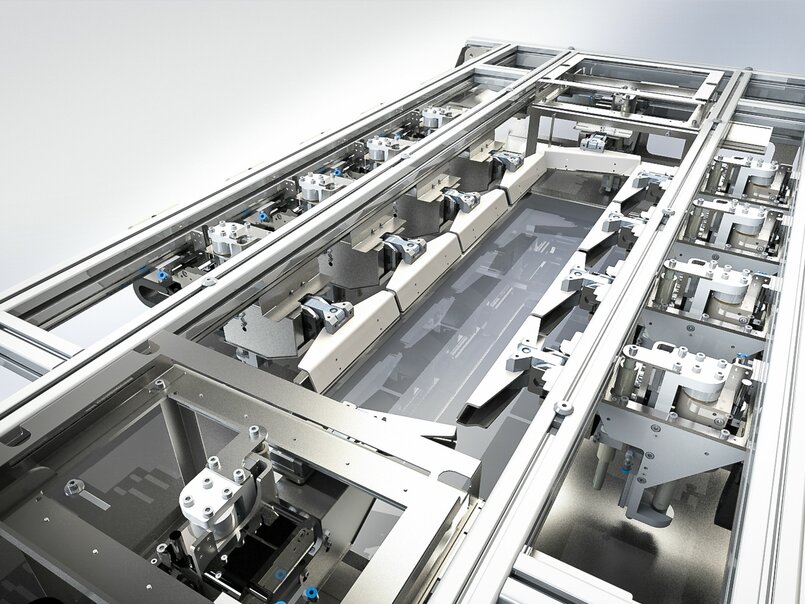

But what's the secret of the new FLF process? The innovation lies in the use of precision film blanks for each component, leaving hardly any waste in the laminating films. The heart of the process is a specially developed gripper system capable of 3D movement. This positions the film on the carrier part without any stretching, before the tool closes and the film and carrier part are glued.

The process at a glance

A highly flexible, modular system concept with a high level of automation enables low-personnel production. The materials, such as precision blanks and carrier parts, come from upstream processes, and wherever possible are already positioned - robots handle subsequent further steps.

By integrating subsequent work steps such as punching and edge-folding, a finished component is available at the end of the line. Compared to conventional manufacturing processes, the total footprint is significantly lower - saving up to 50 percent of costly production space.

Millions of cost savings

“The highlights of the new technology are undoubtedly film savings together with improved surface quality. This is combined with a reduced component cost, which quickly adds up to several million Euros over the production lifetime of a model series”, explains Kiefel sales manager Wolfgang Eglseer. In addition, FLF technology meets the current requirements of the automotive industry in terms of automation and footprint reduction.