Innovative cooling concept reduces maintenance costs

28 Jan 2020

New situation-specific cooling of thermoforming tools reduces wear

It's annoying when a thermoforming tool wears out quickly, the service life is too short, the maintenance and resulting costs are too high. This can often be traced to the tool cooling. The current systems usually inaccurately regulate and record the temperatures. Internal temperatures are the key for wear of fall-through cutting tools.

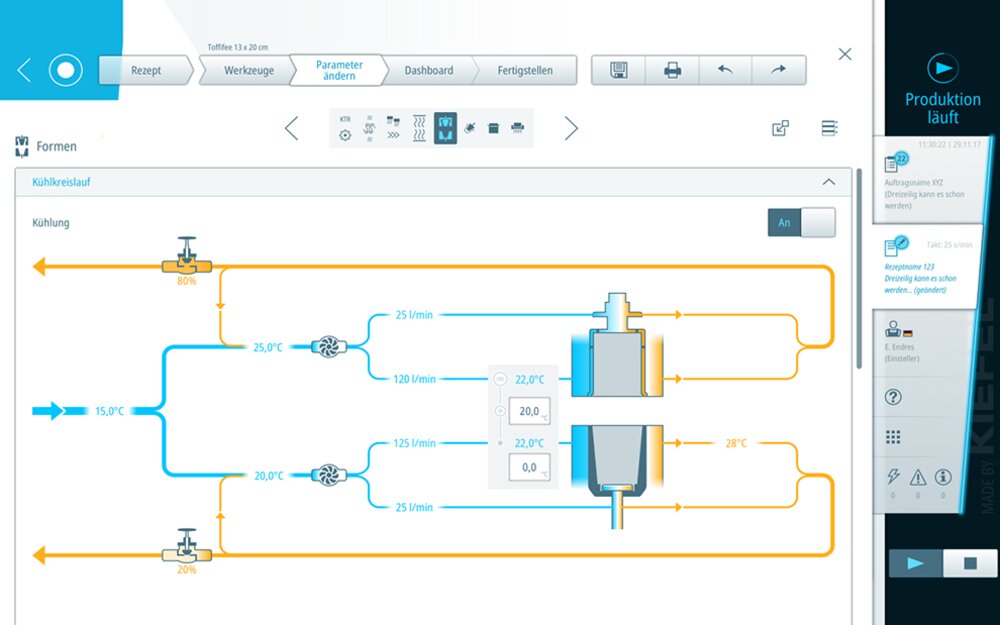

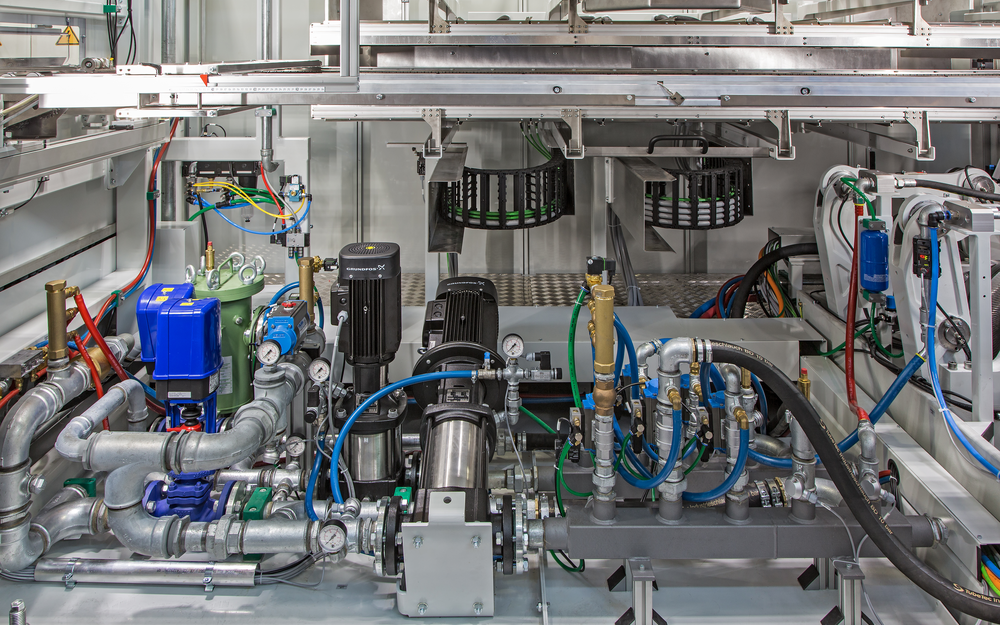

The specialists at Kiefel, Freilassing, have taken on this problem and developed a solution. The new tool cooling system is fully automatic and sensor-controlled. This innovation has an especially positive effect on tool life and product quality. The tools utilize two separate cooling circuits for the upper and lower tool and an extended sensor system for optimum control. Two pumps and mixer valves supply the two circuits with cooling water; the integrated temperature control ensures optimal tool protection. Start automation is sensor-controlled, completely eliminating overshooting of the lower tool.

The critical moment

The production start of the machine is the critical moment for the temperature regulation of the tool halves. The cooling integrated in the tool must be capable of compensating heat output that can rapidly rise by up to 40kW. The result: uneven temperature distribution within the tool and a high temperature difference between the two tool halves. The very tight manufacturing tolerances of under 3 μm mean that a temperature difference of only 2° C leads to expansion of the material, causing abrasion and, as a result, wear on the tool. The consequence is obvious: The cutting components of the tool have to be reground prematurely. This represents costs of several thousand euros.

Previous attempts have failed to satisfactorily solve the problem. Time and again it has been proven: Higher heat input to the lower tool than to the upper tool may lead to the lower tool needing more cooling power than is available. Its temperature rises. The upper tool can maintain its temperature due to the lower heat input. The temperature-induced material expansion of the tool halves means that the gap between the two tool halves shrinks and wear increases. This phenomenon also occurs when the customer's cooling device is subject to rapid, large temperature fluctuations in the provided cooling water.

The solution

Kiefel has tackled this problem with innovative situation-specific tool cooling. It automatically detects incorrect states and compensates for them e.g. by increasing the temperature of the upper tool when the lower tool temperature increases. The new cooling concept avoids temperature differences between the upper and lower tool.

This is made possible by two different pumps, which supply the two halves of the tool continuously and independently of each other with the maximum possible flow of cooling water. This trick allows the temperature gradients within the tool halves to be kept very low. The temperature of the cooling water is controlled by two separate mixers in the return of the machine, which are controlled by the PLC control. For optimum control, the current temperature values of the tool, the flow and return of the two mixers and the cooling water temperature provided by the customer are cyclically input into the control system. The volume flow in the cooling circuits always remains constant. This control principle constantly provides the optimum cooling water temperature and adjusts the tool temperatures quickly and accurately to the process. Fixtures in particular variable speed pumps or chokes for influencing the flow in the cooling circuits are not installed!

Focus on functioning

The cooling system distinguishes between four different states:

Standby:

In standby, the tool temperature is slowly brought to the temperature desired by the operator and then maintained. Ideally it should be 20°C. In order to avoid unwanted condensation on the tool surface, a temperature of > 20 ° C in standby mode is also possible in tropical countries.

Production start:

This is the most critical situation. At startup, the flow temperature of the cooling water to the tool is initially reduced to prevent excessive heating of the tool. The temperatures and states are compared with the target values at very close intervals, to keep the lower tool temperature below the upper tool temperature. This can lead to minor fluctuations in the tool temperature. To stabilize the process, it is automatically switched to the production state depending on certain criteria.

Production:

During production, the set target values are adjusted as far as the customer cooling water flow temperature allows. The temperatures of the two tool halves are adjusted and regulated independently of each other at all times. Thus, both tool halves always remain within the tolerance window, guaranteeing a long tool life.

Production stop:

When the machine is stopped, the cooling capacity is lowered tool-specifically. This prevents excessive cooling and associated condensation on the tool.

Simple and user-friendly

The Kiefel developers focused on yet another aspect: Operation of the new cooling had to be simple and user-friendly. They succeeded! The cooling activates automatically and only one important value needs to be input by the operator - the desired tool temperature. [see figure 1]. The constant tool temperature at the start of the machine - even with difficult materials - ensures reliable quality from the start.

Kiefel successfully lowered tool maintenance costs with enhanced precision sensor technology and a new, innovative control concept, giving its customers a clear advantage.