Revolution in vacuum lamination: Tailored Blank Technology (TBL)

21 Mar 2019

Completely new vacuum lamination method - the tailored blank lamination process fulfills the high quality requirements of OEMs for increasingly pronounced three-dimensional components with this technology. The new process saves millions in film costs over the vehicle production period.

KIEFEL GmbH, Freilassing, a pioneer in vacuum lamination technology, began development of a completely new vacuum lamination method - the tailored blank lamination process - three years ago. Kiefel fulfills the high quality requirements of OEMs for increasingly pronounced three-dimensional components with this technology. Another bonus: The new process saves millions in film costs over the vehicle production period.

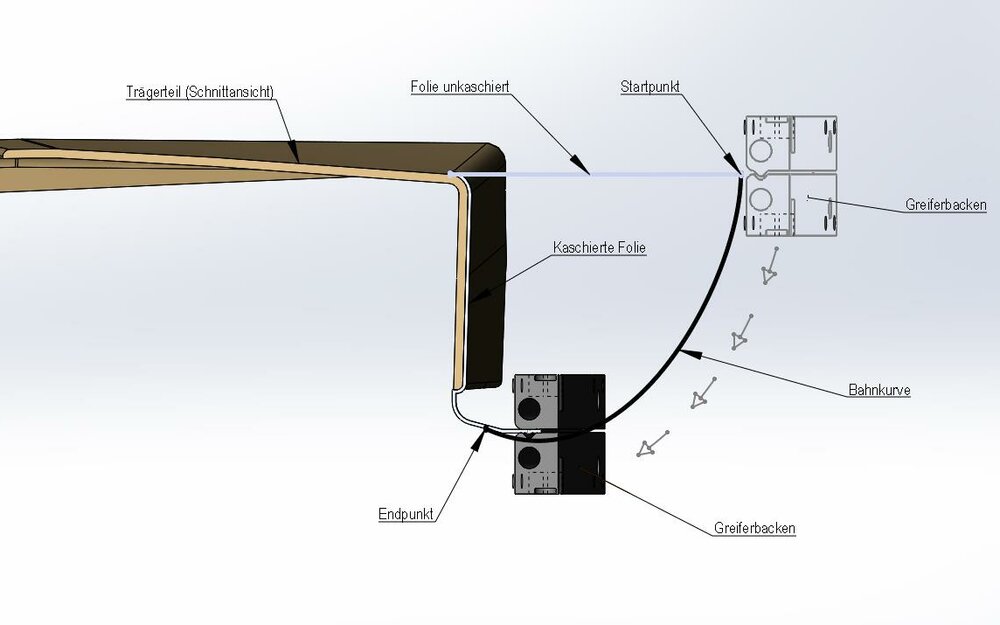

The core of the process: The TBL frame with servo grippers.

The company can now not only present a completely new laminating process - Tailored Blank Laminating - but has also successfully implemented it in a highly automated laminating machine. A peek into the process shows: A stack of film blanks, so-called tailored blanks, is positioned in a hopper for automated picking in the machine. A robot, which is part of the actual vacuum laminating station, picks up the injection-molded carrier parts from a defined point, for example from a paternoster. Individual servomotor-driven axle systems, which can be moved freely in three dimensions, position the decorative material on the carrier part without stretching. This is followed by the laminating process. In the next step, the robot precisely places the components in the next processing machine, such as the edging machine.

The result is a complete processing line. The input material carrier part and decorative trim at the beginning of the line is transformed into finished laminated and edge-folded component - without a human operator. Another aspect of the new TBL vacuum laminating technology, which significantly reduces the cost per unit of the interior components.

CAD data facilitates precise servo gripper trajectories

In order for the new process to deliver the required high laminating quality, each individual servo gripper has to precisely travel the desired and programmed path curve intended for it, guiding the film to the component completely free from deformation and compression. This is the technological basis for the draw-off-free laminating process and is decisive for the high product quality.

On the basis of the CAD data of the carrier components, the Kiefel developers use the processing of the component surface as the basis for the later trajectory of the servo gripper. On the basis of this data, the trajectory is automatically calculated and stored in the program of the respective gripper.

There are several options for defining the starting point of the trajectory. On the one hand, each servo gripper can be adjusted using a mobile device such as a tablet or smartphone. The commissioning engineer can set up and save the individual axes directly at the servo gripper. In addition, the servo gripper can be manually adjusted in "power-off" mode and the desired position can be saved.

High quality components and demanding design

Kiefel's TBL technology produces the highest quality vacuum lamination components whilst minimizing film consumption. Film draw-off levels under 10% across the entire surface of the component with uninterrupted soft-touch is now a reality. The tight radiuses and sharp edge currently so popular with designers can easily be implemented. Precision film positioning via TBL technology permits a radius of 1mm at the injection molded carrier part – while maintaining the soft-touch of the foam film.

At a glance: Customer benefits of TBL technology

- Optimal product quality, film draw-off level max. 10%

- Reduced component costs due to up to 40% lower film consumption

- High degree of automation, unmanned operation

- Servo gripper operation with mobile end device

- Automation of downstream processes such as edge-folding integrated

- Simple commissioning and program optimization

- Outstanding freedom of design thank to tight radiuses and sharp edges of components being possible