New recycling options for printed PP films

13 Jan 2022

Successful thermoforming of films with a recycled component from post-industrial waste.

The research initiative PrintCYC, of which KIEFEL GmbH is a member, has gained further insights into promoting the circular economy of plastic packaging through material recycling. PU-based printing inks allowed the production of color-stable, odorless and defect-free recyclates from fully printed PP-based packaging films by mechanical material recycling, incorporated into flat films without any problems and deep-drawn on thermoforming machines from Kiefel with lower energy consumption. This will open up new possibilities for recycling post-industrial printed film waste and potential for zero-waste production along the value chain of PP-based packaging for packaging manufacturers.

Alternative to non-food packaging made from virgin material

Kiefel has successfully thermoformed both colored trays and cups from the recycled PP flat films, on the KMD and KTR series machines. "The machine set-tings practically did not have to be changed from processing of new material," emphasizes Olaf Tanner, Head of Project and Product Management in the Packaging division at Kiefel.

"The shape, appearance and functionality of the deep-drawn, recycled packaging is so good that it represents a real alternative to non-food packaging made from virgin material."

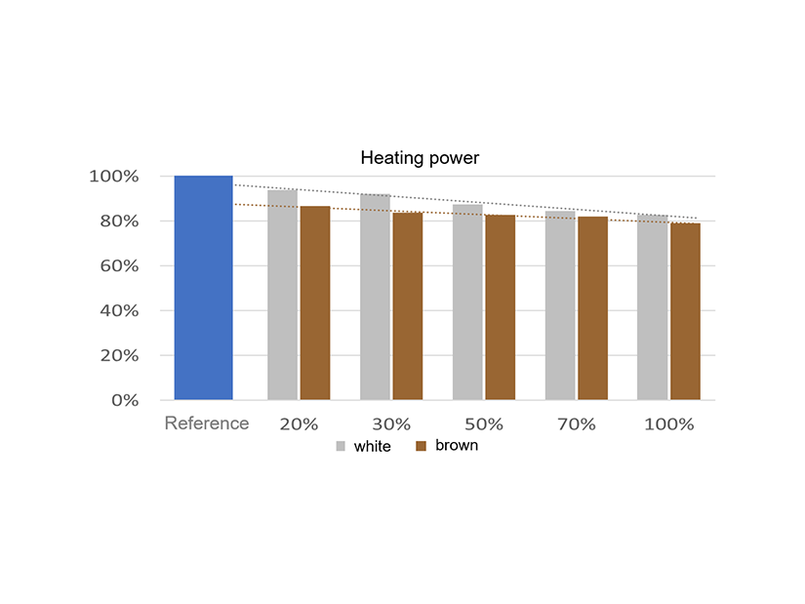

Energy savings of up to 20%

In addition, with the increasing proportion of recycled material, savings of up to 20% in heating energy could be observed in the production of deep-drawn PP cups compared to virgin material. This effect can even be further enhanced through the use of dark recyclates due to the better heat absorption. “As a re-sult, we can operate our machines with a shorter heating time,” adds Tanner.

This opens up interesting possibilities for packaging manufacturers to reduce the proportion of new materials in their containers to contribute to the climate and to save energy.

Production of recycled PP flat films

The recyclates have also been incorporated up to 100% into the middle layer of ABA flat film structures of different thicknesses (500 μm, 800 μm) without any issues. The use of extrusion technology, equipped with a single screw without degassing or a twin screw with degassing, has proven equally suitable for producing color films free of defects and odors with excellent thickness uniformity and stretchability.

About PrintCYC

PrintCYC is an initiative along the entire packaging value chain for the recycling of printed films. The consortium utilizes fact-based industrial tests to showcase solutions for a circular economy of printed PP-based packaging films. The initiative includes the machine suppliers Brückner Maschinenbau. Kiefel and PackSys Global, Profol, the specialist for flat films made of PP (polypropylene), the printing ink manufacturer hubergroup Print Solutions, and Erema, the specialist for recycling technology. The initiative is coordinated by Dr. Annett Kaeding-Koppers, an independent consultant for sustainable packaging solutions.