Taking the development of pulp packaging to the next level

16 Feb 2022

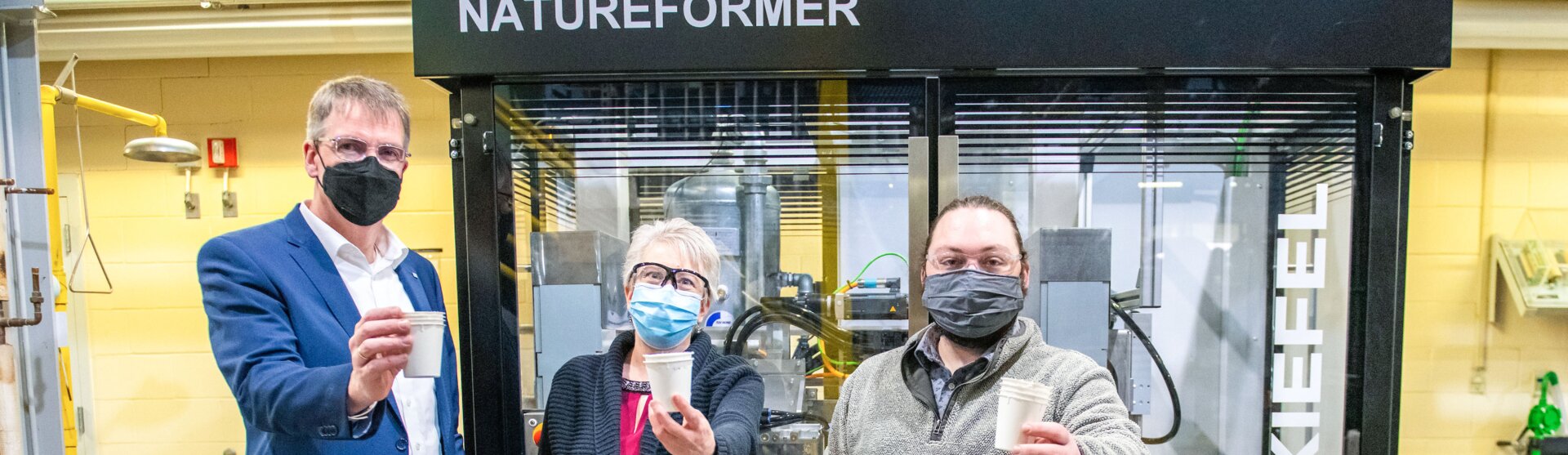

Kiefel equips University of Maine with new laboratory machine for natural fiber packaging

Portsmouth, New Hampshire/ Orono, Maine. The University of Maine can now drive the development of molded pulp products even further. On Monday they put into operation the brand-new laboratory machine NATUREFORMER KFT Lab from Kiefel, a market-leading specialist in thermoforming and joining technology, represented by Brueckner Group USA (BGU). On the machine, students can now explore the fiber thermoforming technology and conduct research on sustainable materials, using cellulose nanofiber (CNF) technology.

Fiber Thermoforming technology allows Kiefel machines to manufacture packaging from natural fibers such as cellulose, straw or annual plants. In certain fields of application, the packaging offers an alternative to conventional plastic packaging. Kiefel developed the associated NATUREFORMER machines for series production over the past three years - a large number is already in operation worldwide.

Strengthening innovative power through partnerships

“We´re happy to support the training of the next generation of engineers for the molded paper field with our machine”, says Matthias Sieverding, CEO of BGU, during the handover to the university. “Natural fibers hold huge potential for sustainable everyday applications. We see public private partnerships like this one as key to accelerating research activities in this important field – and to also educate the public about the possibilities.” Kiefel is therefore building up a network of material and research facilities worldwide for the molded pulp industry including customers and raw material suppliers.

Colleen C. Walker (Ph.D.), Director of the university´s Process Development Center, adds: “As we enjoy a first-class reputation when it comes to research and development, excellent equipment is important. Our students will be able to use the KFT Lab machine to produce small test batches and research various formulations including barrier properties of natural fiber products using our own CNF technology.”

Fostering sustainable developments

Kiefel is committed to increasing sustainability on many levels and has integrated the sustainability aspect even further into corporate strategy. One result has been the expansion of materials processing expertise from polymers to natural fibers. The company also participates in various initiatives to improve the recyclability of plastics, such as HolyGrail and PrintCYC. In addition, Kiefel continuously optimizes activities related to products, technologies and companies.