Thermoforming meets fiber

16 Apr 2020

Plastics Know-How for Fiber Processing

"Reduce - Reuse - Recycle" should be more than just empty buzzwords, they should be brought to life. KIEFEL GmbH, Freilassing, is a technology partner in various domains of the plastics and packaging industry, where it supports customers in the development of sustainable materials and products. In addition to classic recyclable plastic, Kiefel systems can also process recycled (e.g. rPET) or bio-based materials (e.g. PLA).

“More and more customers are asking us about technology that they can use to produce high-quality cellulose-based packaging. Our fiber thermoforming systems provide a solution that complements plastic processing,” says Erwin Wabnig, Head of Fiber Thermoforming, describing the evolution of the new machine “NATUREFORMER”. This enables Kiefel to provide the right machine technology - whichever material the customer chooses.

With fiber thermoforming, the company has opened up a complementary technology field with a new material - incorporating decades of thermoforming machine design know-how. There is a good reason for calling the process of the new NATUREFORMER machine "Kiefel-Fiber-Thermoforming" or KFT for short. Wabnig confirms: “Paper products can hardly be distinguished from those made of plastic in terms of appearance. For example, applications include inlays for high-quality electronic devices that look classy and fulfill their protective function. ”The advantage is obvious: In this case, all of the packaging – the outer packaging and inlay - consists of a single material; paper fiber, meaning no material separation is necessary before recycling.

Machine under the microscope

The similarity of the NATUREFORMER KFT 90 to the classic KMD steel rule machine is unmistakable. No wonder, because the engineering company from Freilassing has utilised proven plastics processing technology for the KFT.

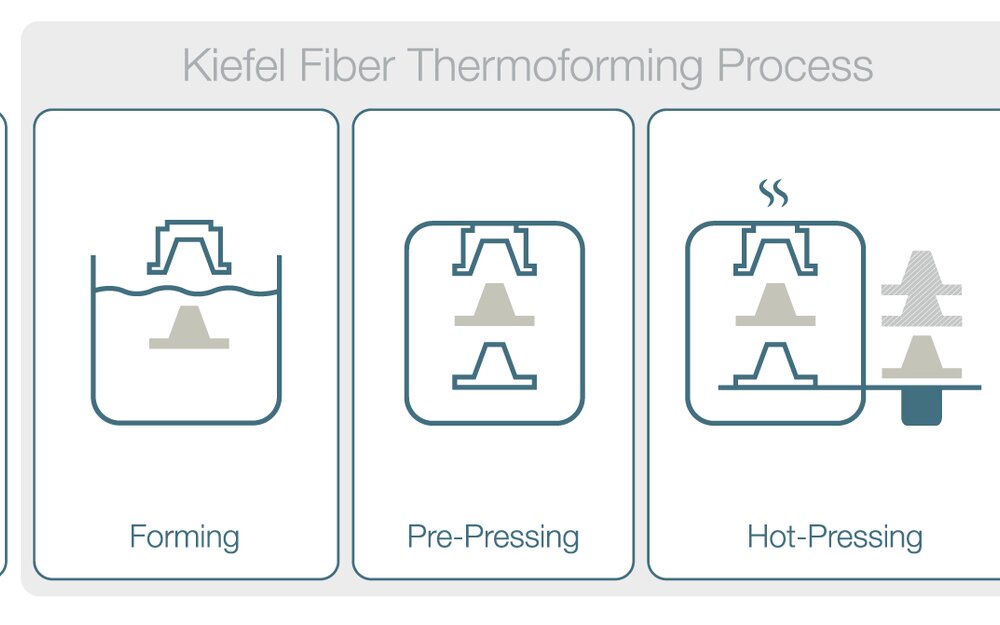

The raw paper pulp is processed in batches up to 1% fiber content. Flow simulations ensure that the fibers are evenly distributed over the basin volume. The metal mesh suction tool dips into the slurry, the vacuum sucks up liquid and leaves the fibers in the form of a filter cake in the tool. A spray bar cleans the edge of the tool and removes excess pulp. The suction tool then moves into a flexible counter tool of the pre-pressing station. Alexander Huber, Fiber Product Manager, illustrates: "The flexible pre-pressing tool ensures very even fiber distribution across the entire tool geometry."

After this step, the fiber content reaches approximately 40%. The suction tool then transfers the component to the hot press. Any remaining moisture is eliminated by temperatures up to 200°C in the upper and lower tools in combination with a clamping force of up to 600 kN. Huber explains: “Our technology allows us to achieve product heights up to 250 mm. We work with cavities which are direct heated by heating cartridges. The heating cartridges are integrated in the hot-press tool. This enables us to achieve optimal heat transfer, reduce energy consumption and achieve high product quality."

The suction tool is mounted on the handling robot and transfers the component from station to station. Defined tool positions for maintenance, cleaning and tool change can be reached in this way. The NATUREFORMER KTR 90 tool change is completed within 15 minutes thanks to the automated quick-change system. Kiefel adapts machine automation - stacking, sleeving, packing in boxes - to customer requirements. Quality control and inspection measures can be integrated into the machine via additional modules.

A full scale pilot system is already running, producing Kiefel reference cups with a cycle time of 15 seconds. Huber emphasizes: “We now have numerous systems in our order backlog. We will deliver the first to a customer in the middle of this year.” This makes Kiefel the first plastic thermoforming machine manufacturer to offer highly automated systems for fiber thermoforming.