NATUREFORMER KFT - speed up sustainable growth with strong partners

16 Mar 2022

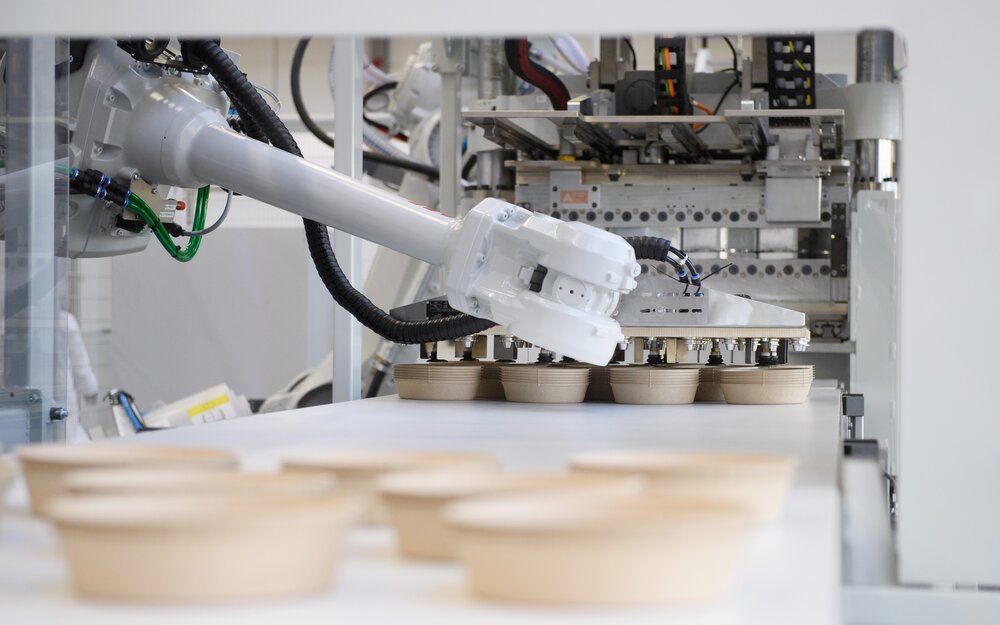

An article from Siemens AG: Thermoforming with a green core - the world has a waste problem. Every year, every person in the EU produces an average of 33 kilograms of plastic packaging waste. Compostable solutions made from natural fibers can be a way out. A new machine series designed and produced by KIEFEL brings this alternative to the market – supported by systems and solutions from Siemens.

Developing the new machine series was a very personal mission for Thomas Halletz, CEO of Kiefel. “We’ve all seen images of carelessly discarded plastic waste and its consequences for marine and river ecosystems. And a large share of this plastic waste consists of packaging materials. I strongly believe that it is our shared responsibility to develop both solutions for an effective recycling system and alternative packaging solutions where they make sense.”

Strong words coming from the CEO of a company that has been a leader in designing and building machines for plastics processing for more than 60 years. But Kiefel has already started rethinking packaging, as Thomas Halletz confirms: “For many years now, we have been investing in solutions that make our thermoforming technologies more sustainable and resource-efficient, through recyclable products or products made from recycled materials or bio-based plastic.” But the Freilassing-based company was aiming even higher: “Then we asked ourselves, why not simply use natural fibers to complement plastic materials as packaging – fibers that come from nature and can go back into nature after use, ideally even being compostable. That was when we started developing NATUREFORMER.”

A synthesis of new and proven technologies

Thermoformed products from natural fibers such as cellulose are nothing new, but the processes and technologies used in their production were dated. “The corresponding process know-how has virtually gone extinct in the European industry,” says Matthias Hausmann, head of central R&D at Kiefel. This was why he and his team were challenged to combine Kiefel’s thermoforming expertise with knowledge of natural fibers and cellulose processing. This task required taking a pioneer’s stance, as Thomas Halletz confirms. New materials, new processes, and new tools added up to an impressive list of to-dos for the project team. But Matthias Hausmann also points to the company’s strengths: “What sets us apart is that we really know how to build thermoforming machines and automate thermoforming processes. That gave us a solid foundation and enabled us to focus on the new technologies and issues.”

Automation was a safe bet

The Kiefel solution expertise includes an automation platform that is standardized wherever possible, explains Matthias Hausmann. “We have entered into a strategic partnership with Siemens in that field and co-developed solutions for automatic thermoforming. This partnership has really paid off, as Siemens offers a perfect portfolio for our purposes and has a wide range of systems. When we introduce a new design, we never have to worry whether we can implement the automation, as we know that it will work.”

Fast-tracking development

This solid foundation was especially important because Kiefel needed to develop the NATUREFORMER series in an extremely short time. “We were fully aware that entering the market for natural fiber thermoforming came with some risks. But right from the start, we had clear feedback from the market that this idea would be well received – that is, if we could industrialize it, offering high efficiency, quality, and speed. So we decided to take on the challenge,” Thomas Halletz explains.

Kiefel invested in a new materials lab, a technology center, and training, and performed lab tests and transferred the results to the machine solution. “We were working with a very dynamic mindset and a highly motivated team, and we have maintained that spirit to this day,” Matthias Hausmann says with some pride. Just three months after the official start, he and his team were performing the first test runs on the lab machine. Today, just three years after the initial idea, dozens of machines are ready for delivery in the final assembly, with many more machines already commissioned all over the world.

The right idea at the right time

The right combination of materials, process, and production expertise has made the Kiefel NATUREFORMER series an instant success with many producers. Kiefel was recently awarded a large contract for more than 100 machines by a US-based company. For a medium-sized company like Kiefel, this success again presented some new challenges, Thomas Halletz admits: “We needed to rise to this task and optimize internal operations in construction and in our supply chain so that we could handle such a large order efficiently.” Again, the partnership with Siemens has proven its value, says Hausmann: “With Siemens we can rely on a technology that we can offer to customers all over the world. Spare parts and service are readily available no matter where you are. That takes a load off our shoulders.” Kiefel could also count on the Siemens performance and reliability when the company needed support during construction. A large proportion of the electrical and control cabinets for the NATUREFORMER series are being built at one of Siemens’ facilities.

New ideas for sustainable products

The bottom line: Kiefel is currently commissioning at least one new machine at a customer facility every day, but the project team is nevertheless already working on improving the process and the machine solution. According to Matthias Hausmann, “The good thing about having a new technology is that there is so much room for improvement. For instance, we have implemented systems for recycling water and process heat to lower the energy consumption in the process to 2.5kW per product, which is an absolute benchmark.” Sustainability at Kiefel also includes designing machines so that they not only produce sustainable products but are sustainable themselves. In terms of long-term performance and investment protection, Kiefel is currently migrating to the new motion control platform from Siemens, which will enable the company to explore new options for networking machines and using data-based services. In this too, Kiefel benefits from working with Siemens, a pioneer in OT/IT integration and software management. “Especially when you look at innovative processes, the value-add of automation is already high today and will continue to grow,” says Matthias Hausmann. With Siemens, Kiefel has found the perfect partner and is well positioned for sustainable growth.

______________________________________

Video & music produced by Siemens AG