Maintenance made easy

18 Aug 2022

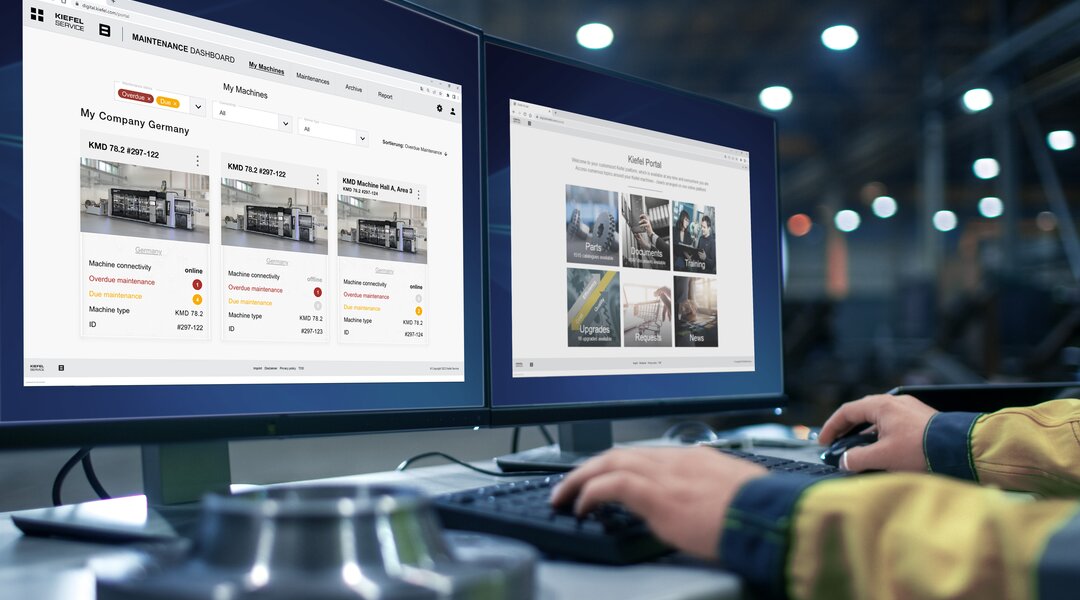

New Maintenance Dashboard for proactive machine maintenance

A functioning maintenance management system is key to safe and efficient production. We are developing the Maintenance Dashboard, an instrument that makes maintenance easier for our customers. The Maintenance Dashboard, which runs on the central Kiefel Portal online platform, will give Kiefel customers an overview of the machine status of all machines in their fleet on one platform, 24/7. It allows proactive planning of all maintenance work and provides employees with all the information they need. It will be on display for the first time at the K 2022 in Hall 3, Stand E 90.

Michael Strasser, project manager for digitization at Kiefel, explains: "A survey of our customers showed that the maintenance managers want an overview, instructions for maintenance and qualification measures for their team - and all of that online. It is important to them that all employees are provided with the information they need for maintenance tasks. And that they can carry out maintenance effectively at the right time.”

Proactive maintenance at a click

The new Maintenance Dashboard will fulfill all of these wishes. It shows all of the customer's machines at a glance and reveals whether they are currently operating, whether maintenance is soon due or overdue. A click on one of the machines takes the user deeper into what is happening. For example: the machine is overdue to be cleaned or the filter of the pneumatic unit soon needs to be changed. The maintenance team sees the intervals at which the various maintenance work is scheduled and how many operating hours are left before their next task. This makes predictive maintenance easy to implement. Strasser explains: "Maintenance thus retains an overview, can better plan upcoming activities and thus ensure maximum availability of the machines."

Defined maintenance tasks, such as cleaning the machine, can be emailed directly from the Maintenance Dashboard to the responsible employee. They then see which sections they need to clean and how to proceed step by step. A component drawing with labels reveals where the elements to be cleaned are located.

Secure archiving

The information in the Maintenance Dashboard is based on real data that converges in the cloud. All data on all previously carried out maintenance work is also stored here. This archive function makes it possible, for example, to view maintenance processes from the last twelve months. Strasser thinks that's a real bonus: "This data archive makes it very easy to provide the auditor with all the necessary data for an ISO audit at the click of a mouse. And: I can track the history of each and every individual machine.”