Great electrical support during service emergency

16 Apr 2019

Improved line availability with integrated process control (IPC) upgrade

Garware Polyester Ltd., one of the largest manufacturer of polyester films in India, teamed up with Brückner Servtec to maximize the availability of their line no. 5 in Aurangabad with a comprehensive software and automation hardware upgrade. The BOPET line, which has been installed by Brückner in 1996, will be equipped with a brand new IPC system to make it ready for the future and increase its availability. The implementation on-site will start in the middle of 2019.

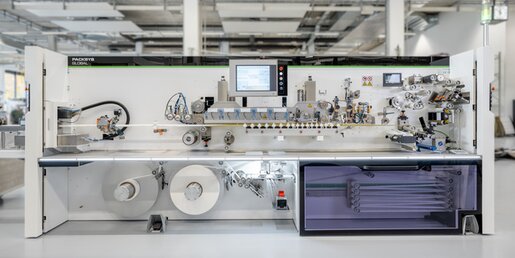

With Brückner’s IPC, Garware will have one single system for the control and visualization of the entire film production line. The system is specifically developed to the needs of the film production industry and makes the line’s operation, maintenance and support much easier:

Within the IPC-upgrade, Brückner installs a new Programmable Logic Controller (PLC) S7 and the latest process visualization software WinCC-OA Server. For the new PLC, Brückner will check all signal inputs and outputs (I/O), which is a complete electrical maintenance and service of the whole line. Additionally, each line component will receive new operator stations for the revolutionary 8-Mode-Operation. It enables a faster and repeatable start-up of production by using pre-defined operation states such as “purging”, “threading in MDO or TDO” or “production”. Furthermore, the IPC modification replaces obsolete hardware, which ensures the future availability, reliability and support of server, workstations and PLC. The line’s system will have latest technology and the spare parts supply will be secured for the future.

The risk of obsolete hardware

The consequences of obsolete hardware showed up also during a service emergency support at the line recently. The customer reported that several workstations at the pull roll did not work no longer, and they could not operate the line, since the visualization failed. Immediately, Brückner service experts tried to log into the system remotely, however it did not work because the server did not communicate anymore. With the help of Brückner’s knowledge and experience, it became apparent after several tests that an old Motorola PC failed. Unfortunately, a new spare Motorola PC was not available anymore in the market.

However, Garware still had a spare PC available, that Brückner installed in 1996 during the initial commissioning of the line. The customer installed the spare PC and the Brückner team supported the team on-site during the installation and new start of the BOPET line. Finally, all workstations run again and the Brückner Servtec experts could save the old IPC system and supported the customer with a temporary solution, until the new IPC system will be implemented.

Garware’s General Manager of the Electrical Department was very happy: “We thank Brückner Servtec for the quick support. It was a challenging situation for both sides to make the obsolete server working again. Thanks to the Brückner specialists’ hard work and expertise, we could restart the production. We will have more peace of mind again, when Brückner implements the new IPC system in June and our line will be equipped with state-of-the-art technology with secured spare parts supply.”